U.S. Company Makes Bandaids From Lobster Shells

Lobster Tough, a company in Maine is developing a bandage coated with a substance extracted from crushed lobster shells that would promote blood-clotting and is resistant to bacterial infection.

Lobster shells from Maine have been shipped to a processor in Iceland for testing. According to Thor Sigfusson, a spokesman for an Icelandic investment firm with a stake in Lobster Tough, the results are very promising.

Lobster shells usually end up in landfills after the meat is removed. Using lobster shells to create a medical product would create more value for lobsters and boost the industry in Maine, according to Sigfusson.

“My dream will be to use the massive amounts of lobster shells that are being thrown into dumpsters,” he said.

Chitosan, the blood-clotting compound, is currently produced industrially by crushing shrimp shells and washing the solids with acids to remove inorganic materials and proteins. The U.S. Army has used field bandages treated with chitosan processed from shrimp shells. Industry leading companies like Celox have already created blood clotting products in bandage and powder form for domestic use and are currently the product of choice among elite U.S. Special Operations units.

The Maine lobster shells would be shipped from Portland, ME to Iceland for processing.

The lobster shells must be dehydrated to remove weight and lower shipping costs. Lobster Tough this winter is shipping a portable dehydration machine from Iceland to Maine. The company eventually plans to build a $2 million dehydration plant somewhere on the Maine coast, said Patrick Arnold, an investor who lives in South Portland.

The goal is to introduce the bandages to the U.S. market in 2017, he said.

Maine is known for its pristine environment and sustainable lobster industry, Arnold said. That reputation will help sell the bandages, which will feature cartoon images of lobsters on its packaging.

“The storyline and traceability of the product is important,” he said.

The bandages would be the first commercial product developed through the New England Ocean Cluster, a new business incubator in Portland.

NEW ARRIVALS

NEW ARRIVALS

BEST SELLERS

BEST SELLERS

SUPERSKIN™

SUPERSKIN™

COURSES

COURSES

GIFT CARDS

GIFT CARDS

The MyFAK Collection

The MyFAK Collection

Specialty

Specialty

The Ready Collection

The Ready Collection

BLEED

BLEED

OUTDOOR

OUTDOOR

TOOLS & DEVICES

TOOLS & DEVICES

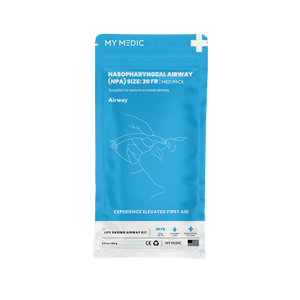

AIRWAY

AIRWAY

BLEED

BLEED

OUTDOOR

OUTDOOR

BURN

BURN

TOPICAL

TOPICAL

MEDICATION

MEDICATION

SPRAIN & FRACTURE

SPRAIN & FRACTURE

HYDRATION

HYDRATION

TOOLS & DEVICES

TOOLS & DEVICES

Supply Categories

Supply Categories

Top Sellers

Top Sellers

Leave a comment